Custom Panels, LLC.

DuraBoard®

trim products are cellular PVC with the unequalled combination of Quality, Durability,

Workability and Beauty. Available in trimboard, cornerboard, and sheet dimensions,

DuraBoard products have the look, feel, and sound of clear, premium lumber. DuraBoard

products are a perfect replacement for wood in all non-structural applications.

Storage and Handling

- Store DuraBoard® products on a

flat and level surface.

- Since DuraBoard® trim products

are more flexible than wood, they may conform to uneven surfaces.

- DuraBoard® trim products have

a density comparable to a soft lumber product and should be handled in a fashion

as pine would be handled to avoid damage.

- Units of DuraBoard® are shipped

from the manufacturer in a protective covering. If covering has been removed, take

care to keep product free of dirt and debris at jobsite. If product gets dirty,

clean after installation.

Cutting, Drilling

and Screwing

- DuraBoard® products can be cut

using the same tools used to cut lumber.

- Carbide tipped blades designed

to cut wood are recommended and work well. Avoid using fine tooth metal cutting blades.

- Rough edges from cutting may be

caused by excessive friction, poor board support, or worn or improper tooling.

- DuraBoard® products can be drilled

using the same tools used to drill lumber.

- Drilling DuraBoard® products is

similar to drilling a hardwood. Care should be taken to avoid frictional

heat build-up.

- Use standard woodworking drills.

Do not use drills made for normal rigid PVC.

- Periodic removal of DuraBoard®

shavings from the drill hole may be necessary.

- Pre-drilling

is recommended when nailing in temperatures below 32ºF.

Routing/Milling

- DuraBoard® products can be routed

using standard router bits and the same tools used to rout lumber.

- Care should be

used to avoid frictional heat build-up.

- Periodic removal

of shaving from the drill hole may be necessary.

- Carbide tipped router bits are

recommended.

- Routing DuraBoard® products provide

a crisp, clean edge.

- DuraBoard® products can be molded/milled

using standard wood-working equipment.

Fastening

- Fasteners

that work well with

wood work as well or

better with DuraBoard® products.

- For best results, use a high quality

fastener such as stainless steel or hot dipped galvanized.

- Standard nail guns work well with

DuraBoard® trim products.

- Avoid fine threaded wood screws

and ring shank fasteners.

- Thinner shanked nails, such as

a box nail, work best.

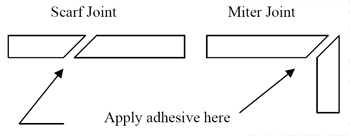

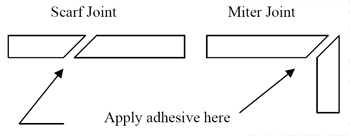

Gluing

- Standard PVC cements, or PVC

glue provide a strong bond.

- For best results, glue all DuraBoard®

joints such as window surrounds, long fascia runs, etc., to prevent joint separation.

- The glue joint should

be secured long enough to allow adequate bonding time.

- To bond DuraBoard® to other substrates,

various adhesives may be used. Consult adhesive labeling to determine suitability.

Painting

- Clean any excess dirt or debris

prior to painting.

- Latex paints are desirable for painting

DuraBoard® products.

Follow the paint manufacturer's recommendations.

Follow the paint manufacturer's recommendations.

- No special surface preparations

are required prior to painting.

- Avoid painting DuraBoard® surfaces

dark colors in areas of direct sunlight.

- Please see the DuraBoard® Painting

Specifications for more information.

General Guidelines

Moisture

- DuraBoard® products do not absorb

moisture; therefore, DuraBoard® products can be installed at or below grade.

- DuraBoard products are perfect

for use in moisture prone applications such as garage doorjambs, ground contact,

masonry contact, hot tub surrounds, freezeboards

and rooflines.

Expansion & Contraction

- DuraBoard® products expand and

contract with changes in temperature.

- Properly fastening the DuraBoard®

material along its entire length will minimize expansion and contraction.

- When properly fastened, allow

1/8" space per 18 foot of DuraBoard® product for expansion and contraction. Joints

between pieces of DuraBoard® should be glued to eliminate joint separation.

- When gaps are glued on a long

run of DuraBoard®, allow expansion and contraction space at ends of the run.

Spanning

- DuraBoard® products MUST NOT be

used in load bearing applications, but may be used in spanned applications such

as soffits and ceilings.

- For soffit installations: For

spans of 16" - 24", use a 1x DuraBoard® product.

- For ceiling installations: For

spans of 16" - 24", use a 1x DuraBoard® product. When using a DuraBoard® product

of 1/2" or 3/8", fasten every 16" or less.

- Never span DuraBoard® products

more than 24".

- Use a mitred joint on spans of

16' or longer to minimize expansion gap on boards. See "Expansion and Contraction"

section above.

Touch Up

- Non-solvent base

fillers are recommended.

- DuraBoard® works

well with All Purpose Painter's Putty and High Performance Wood Filler.

- DuraBoard® also

works well with Fill-N-Finish Light Wood Filler and Shrink Free Spackling.

- Clean DuraBoard®

with soap and water using a damp cloth.

Duraboard - Installation Guidelines

DuraBoard® Installation Guidelines

PLY-TRIM BUILDING PRODUCTS,

LLC.

550 North Meridian Road

Youngstown, OH 44509

Toll Free 800-Ply-Trim (800.759.8746)

Tel 330.799.7876 Fax 330.799.2908

Follow the paint manufacturer's recommendations.

Follow the paint manufacturer's recommendations.